This feature is particularly special as it has taken Infernal Combustion on a historical journey around Bavaria on search of the most authentic and accurate information.

Conventional Engine History

Everything rotates in cycles. This is the view you could reach if you look at the basic principles of nature, because many things that shape our environment and our lives happen in cycles: From the movement of the planets through to the tiniest processes at atomic level – rotating or cycling appears to be the most logical of all movements. What is probably the most significant invention in human history, the wheel, was the first technical implementation to be based on this discovery.

When the gunpowder engine was invented by Christian Huygens in 1673, the search began for a driving force to drive the wheel continuously without the use of any muscle power. The result of the work is what is the reciprocating piston engine as we know it today – a linear force, converted into a rotating motion. James Watt only managed to solve this in 1786 by using a crank and connecting rod, but even back then, he was aware of the deficiency of this technical detour. He was already coming up with plans for rotary engines, but ultimately they failed due to leaks.

Since, the reciprocating piston engine has been retained, along with its drawbacks. It was not just the translation of linear to circular motion that was complicated; the ever more elaborate gas control of these engines has resulted in huge amounts of research and development in the two centuries following its invention.

Alongside the development of the reciprocating piston engine, there was never any shortage of ideas enabling a piston of whatever shape to complete work during a rotating cycle. The majority failed, because there was an even greater problem to overcome; ensuring the sliding seal between the moving bodies and the inner boundaries of the engine.

Early Development of the Rotary Engine

In 1951, the paths of two groups of engineers crossed for the first time: The NSU research department under the stewardship of Dr. Walter Freode and the Lindau Technical Development Agency (Lindau TDE) led by Felix Wankel first came together to solve very different tasks. However, the revolutionary result of their relationship would come as a surprise. Felix Wankel had already been working on the idea of a thermodynamic rotary engine since 1925. In doing so, he had run through many different options and forms in both theory and practice. The brilliant idea of a piston in a triangular form, a design which still prevails today, came to him spontaneously on 13th April 1954.

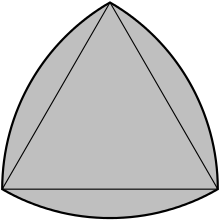

Wankel recognised that a certain overlap of two rotary movements produced a geometric shape in the form of a closed curve – a trochoid. This meant it was possible to conceive of an engine with a casing rotating around itself and a triangular body likewise rotating inside it – a curvilinear triangle. He discovered that, if the sealing elements were arranged correctly in this engine, this produced three chambers which in the circular movement alternately increase and reduce their volume. This provided the basic prerequisite for operation according to the four-stroke principle known from the reciprocating piston engine.

The most fascinating finding was that a four-stroke engine operating in this form could be operated, similar to that of a two-stroke engine, without any valve mechanisms and only via adjustable openings. The ground-breaking rotary engine principle was born.

It was necessary to prove that this theory could be implemented in practice. With the support of Prof. Baier from Stuttgart University of Applied Sciences, the circular shape enveloping the piston housing was defined mathematically as a “two-lobed epitrochoid”, and thus the basis for constructing a special grinding machine for the manufacture of the engine was created. The fact that the path being followed was confirmed to be correct, they began to implement models using rotary piston pumps and rotary compressors. One of the first practical applications was a supercharger operating with this system for the record breaking two-stroke engine of the Baumm II car.

However, the end result of all these efforts was the rotary piston test engine DKM 54, which was started for the first time on 1st February 1957 on a test stand at the NSU research department in Neckarsulm, but only for a short time. Once the alcohol-air mixture had been adjusted and the engine was started again, it began to turn smoothly in the truest sense of the word.

ENGINE: DKM 54

DISPLACEMENT: 125 cc Single Rotor

POWER: 27 hp @ 17,000 rpm

While Felix Wankel worked on optimising the cooling of his rotary piston engine in his technical development agency in Lindau, the NSU engineer Hanns Dieter Paschke, together with his department manager Dr. Walter Froede, started to think about the design in a completely new way. Although the rotary piston engine confirmed that the Wankel principle was feasible, the rotary piston engine was still too impractical for regular use.

Paschke therefore set about simplyfying the engine. Whereas with the rotary piston engine of the DKM 54 the piston (internal rotor) and the housing (external rotor) rotated independently around their own axis, the external rotor was then shut down. Thanks to the kinematic reversal of the principle, both rotary movements are combined on one eccentric shaft: The piston rotating about its path on the eccentric circles, and the revolutions of the eccentric shaft now fixed by a synchronised tooth system. For this purpose, the inner gearing is arrange on one side within the piston and this shifts on the fixed pinion of the shaft which is connected to the engine housing.

Work was conducted at NSU under strict secrecy. Felix Wankel was not to know anything about this work as the feeling was that he would not have approved, but Dr. Freode and his team were certain that an engine which was ultimately suitable for standard use in production could only be obtained through the kinematic reversal of the DKM 54 engine into what is now know as the Wankel Engine.

When Felix Wankel found out about this, he was furious about the new engine: “You have turned my thoroughbred into a plough horse.” The NSU chairman chairman Dr. von Heydekampf replied: “If only we actually had a plough horse!” A few issues with the new engine were already coming to light and so the tests of the DKM 54 were halted in 1958 and a new KKM 57 Wankel rotary engine was started up for the first time on 7th July 1958. KKM 57 was a 125cc Single Rotor engine producing 25 hp @ 11,000 rpm.